1. Raw material preparation

2. Steel pipe pretreatment (degreasing and rust removal, phosphating, drying)

3. Electrostatic spraying and plastic coating (electrostatic adsorption, high temperature curing)

4. Cooling and shaping (water cooling/air cooling)

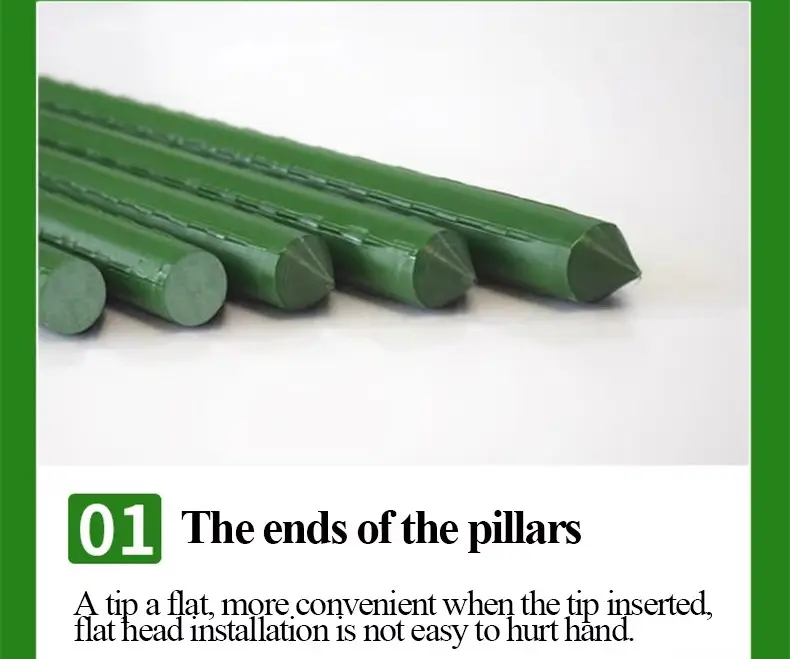

5. Cutting and forming (fixed length cutting, pipe bending)

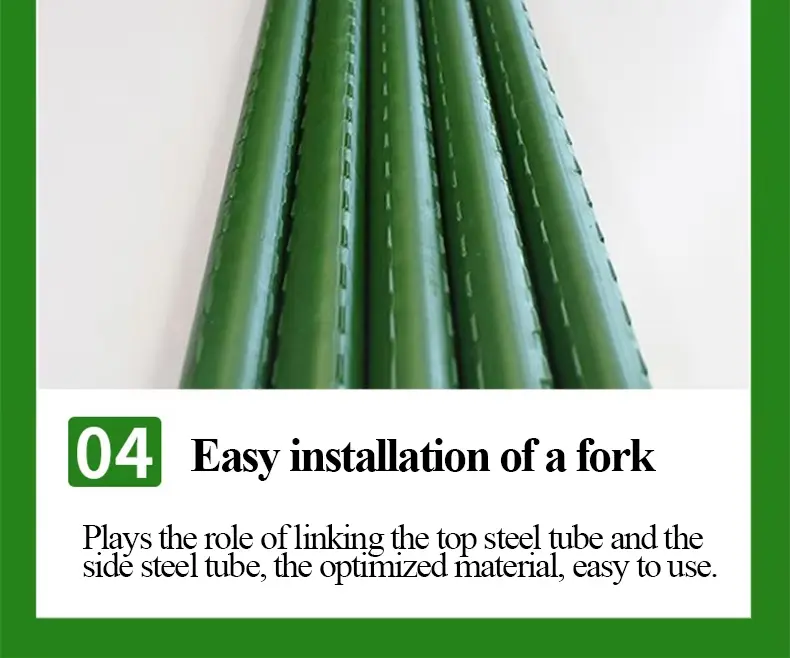

6. Accessory assembly (pre-installed buckles, ground plugs and other accessories)

7. Packaging and warehousing (double-layer protection of foam bags + woven bags to avoid scratching the plastic layer during transportation.)