Forging Strength: The Journey of Steel Trellis Buckles

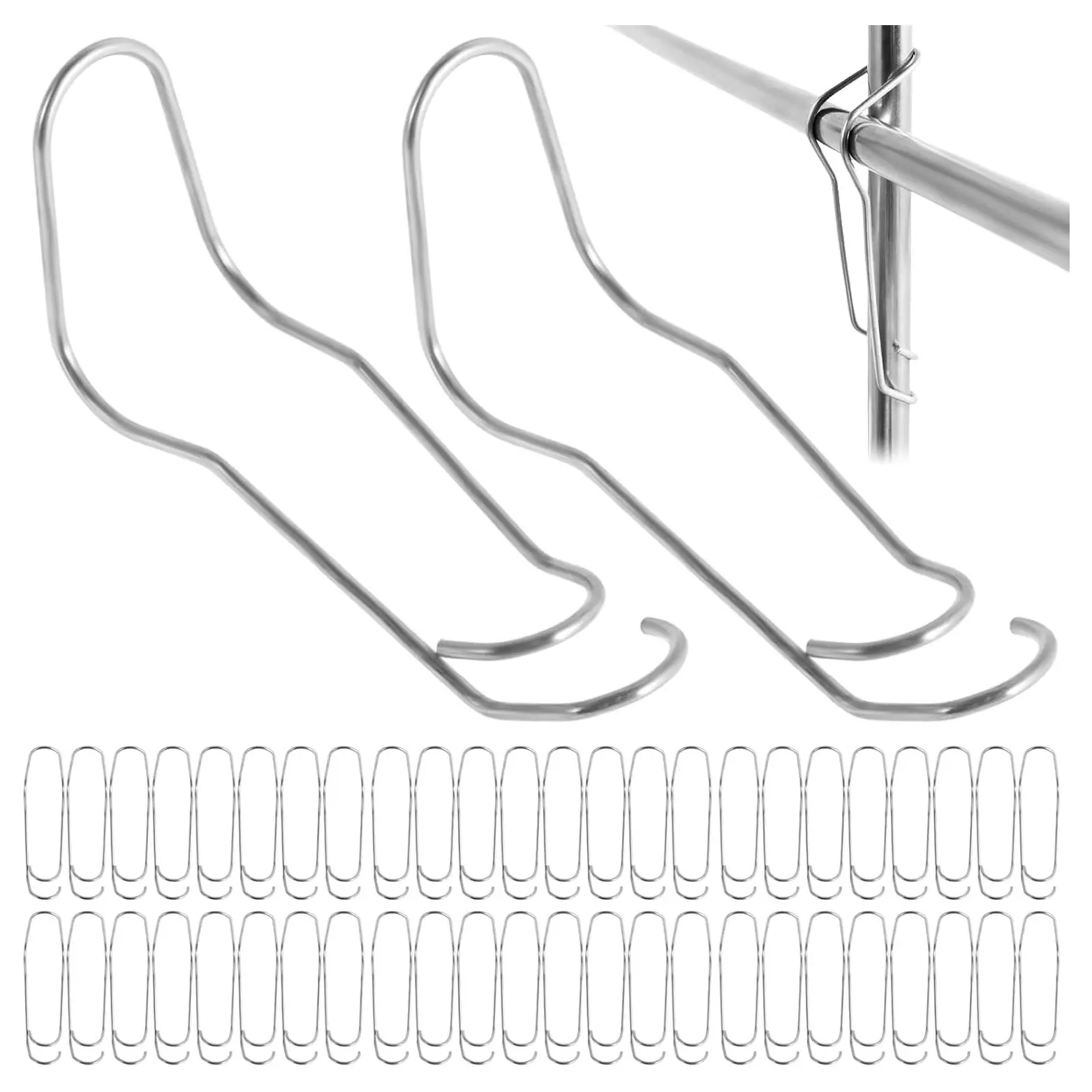

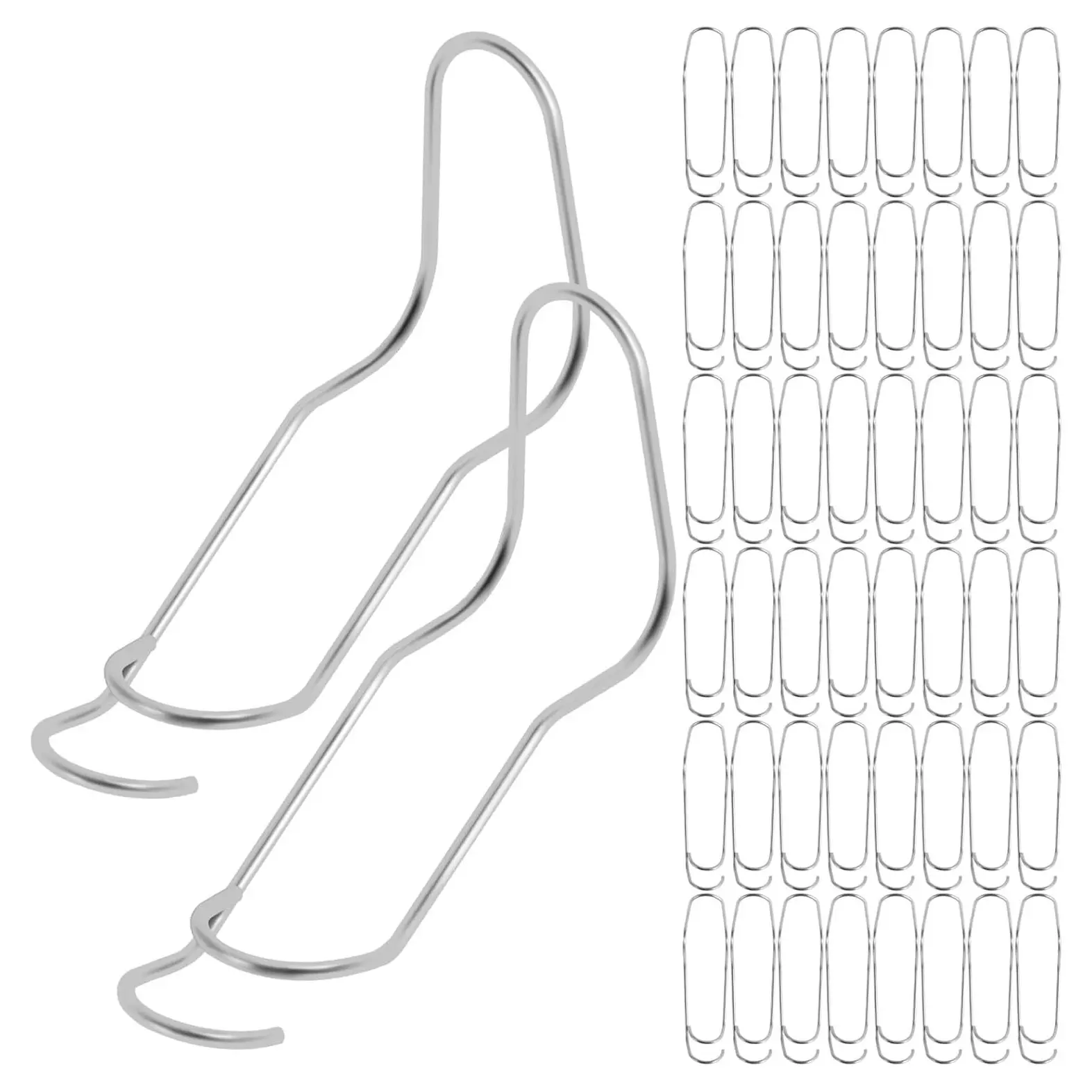

It starts with raw steel – coils of potential arriving at the factory floor. Skilled technicians feed this metal into precision stamping presses, where immense pressure shapes the flat sheets into the distinct buckle forms, ready for their role in the garden.

Freshly stamped parts then embark on a critical cleansing voyage. They journey through chemical baths designed to strip away every trace of oil and emerging rust, followed by a protective phosphating dip that etches a micro-layer of defense right onto the steel surface. A thorough drying cycle prepares them for their next transformation.

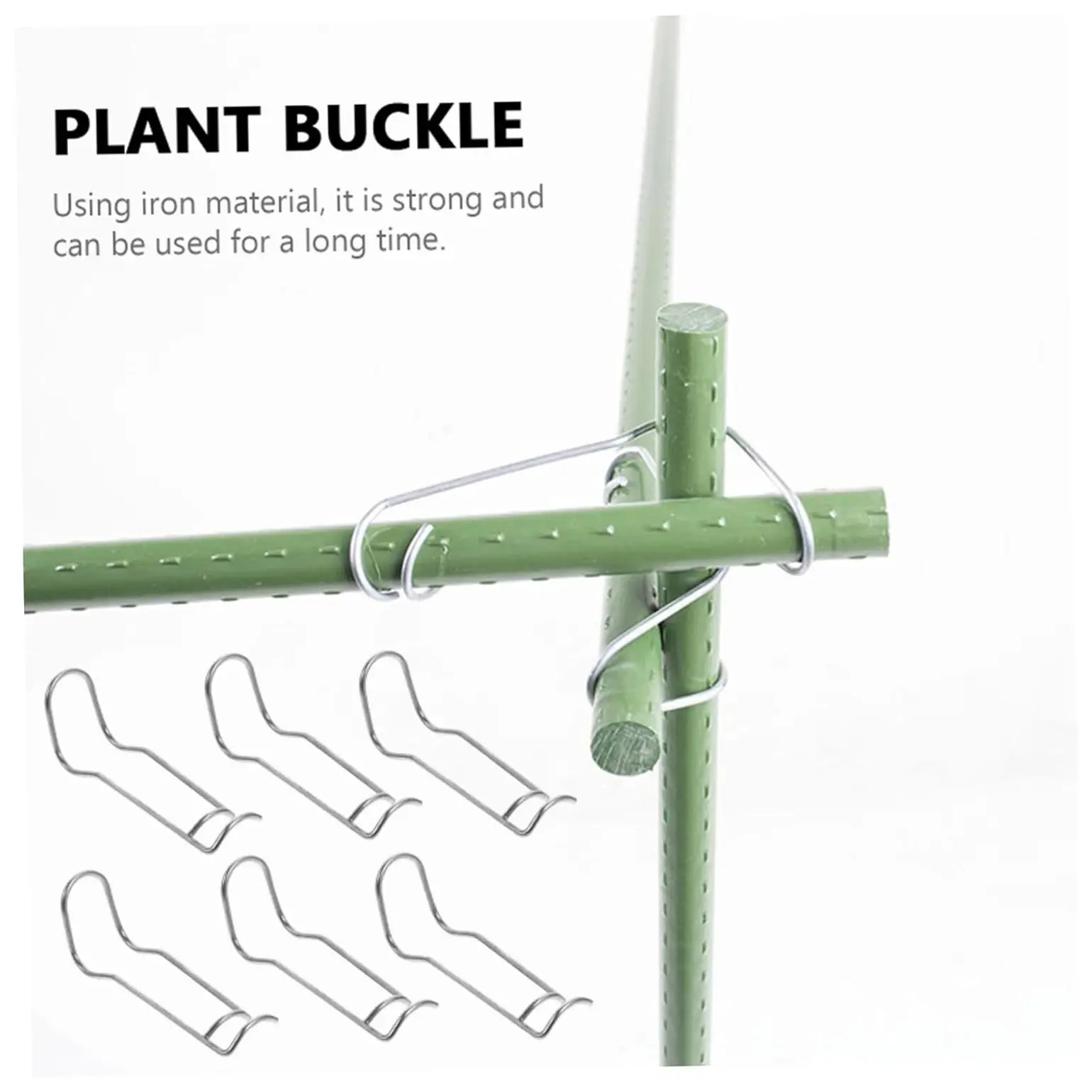

The clean, phosphate-coated buckles now receive their durable skin. They enter an electrostatic chamber where a fine cloud of specialized powder paint clings magnetically to every contour. Moving into intense curing ovens, this powder melts and fuses under high heat, baking into a resilient, weather-resistant finish – often that essential garden green.

Heat demands careful release. The vibrant, coated buckles travel next through controlled cooling zones, whether bathed in gentle air streams or precisely tempered water flows, locking in both their final shape and coating integrity.

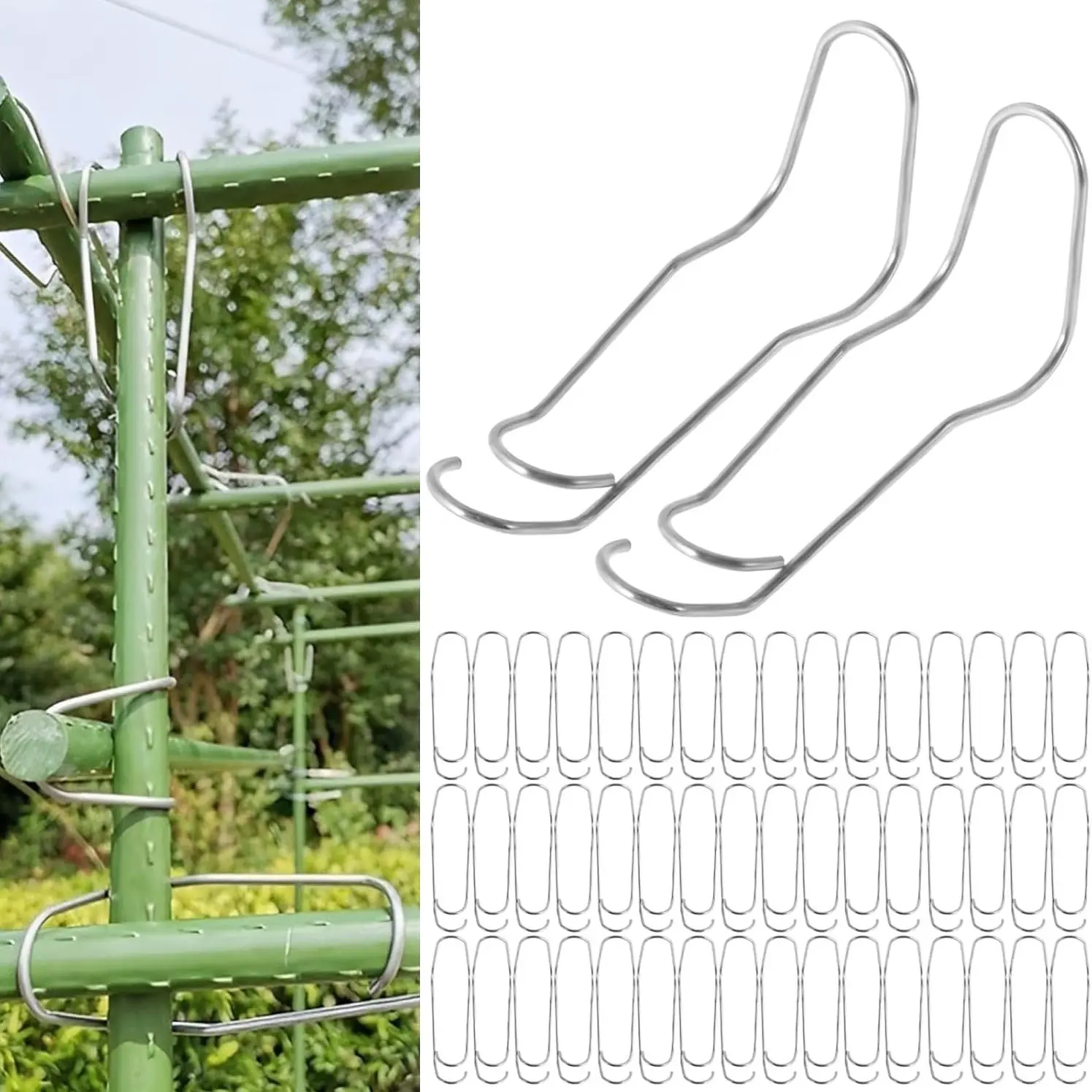

Consistency is key. Once cooled and stable, the buckles meet sharp, calibrated blades that snip connecting pipes or trim any excess material to exact, predetermined lengths.

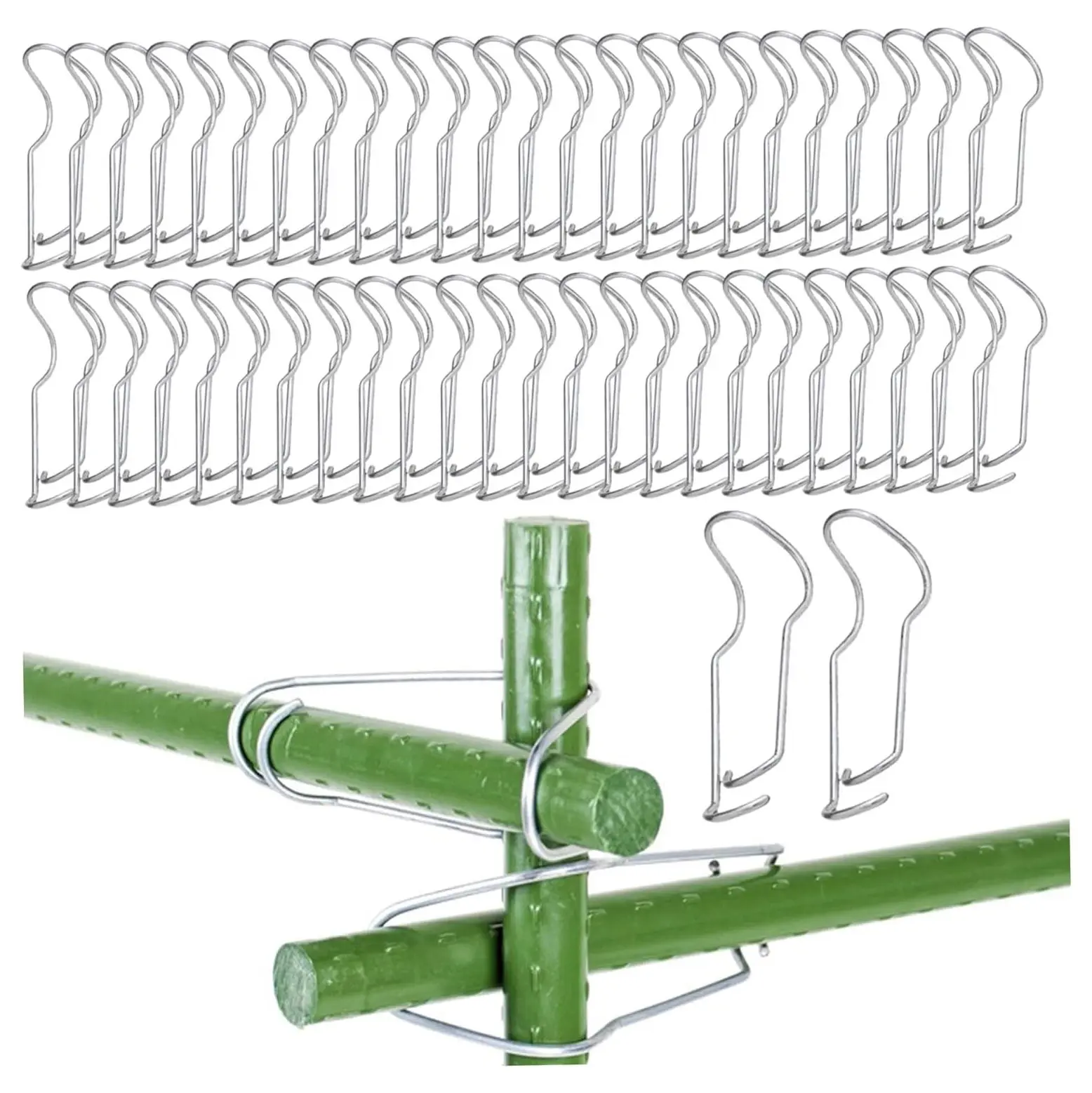

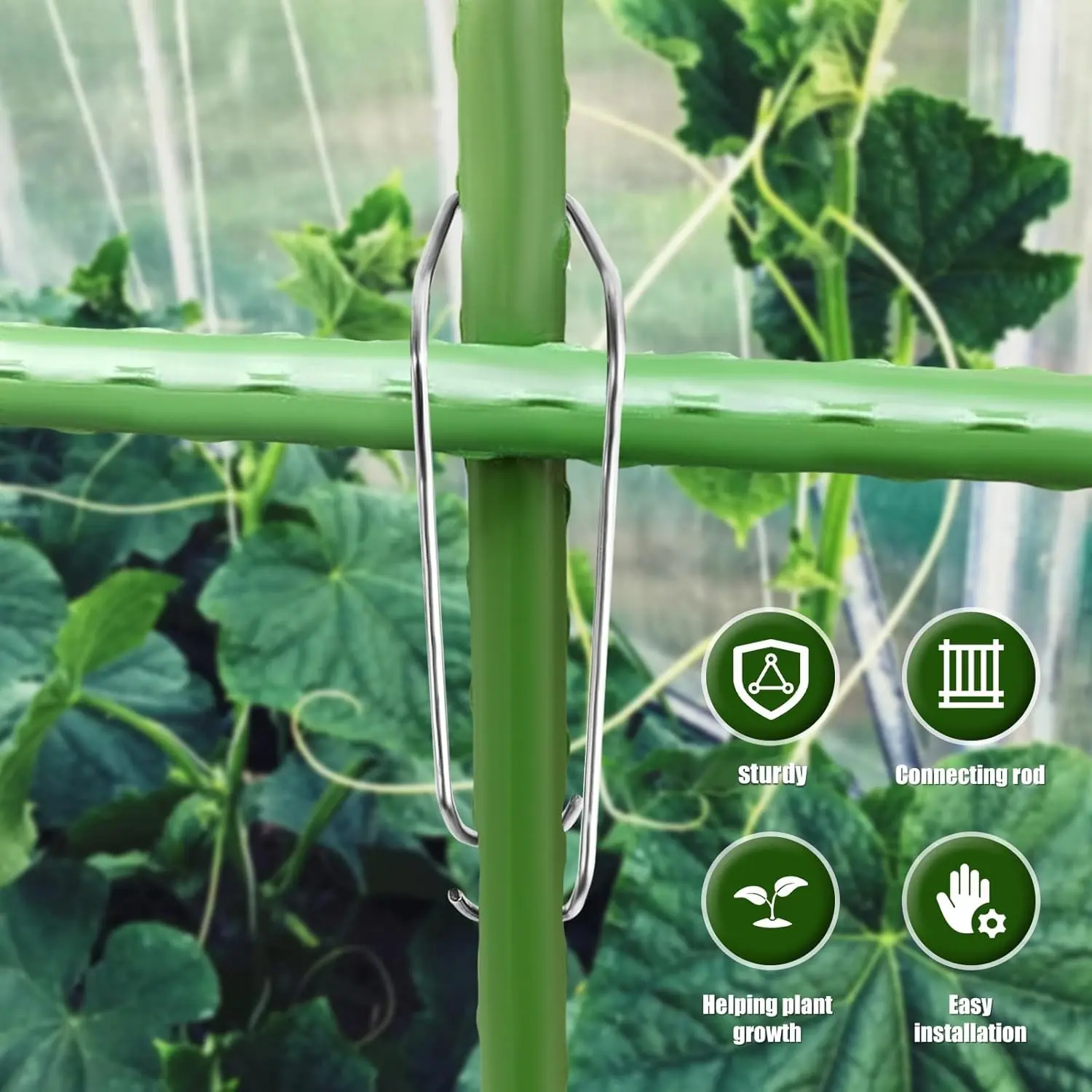

Final touches bring them to life. On dedicated assembly lines, workers deftly integrate any pre-installed fasteners or essential mounting hardware – the small details ensuring easy use in the field.

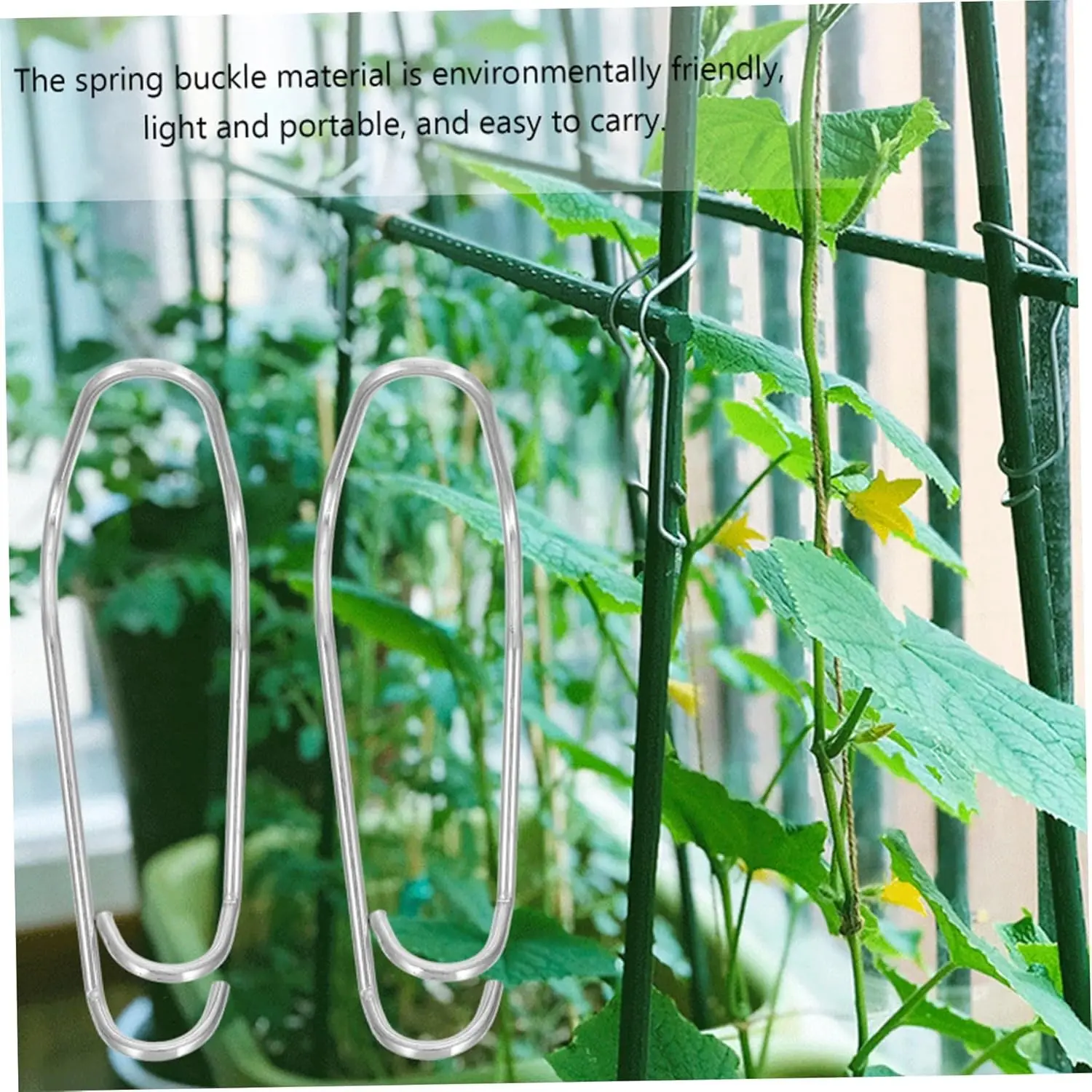

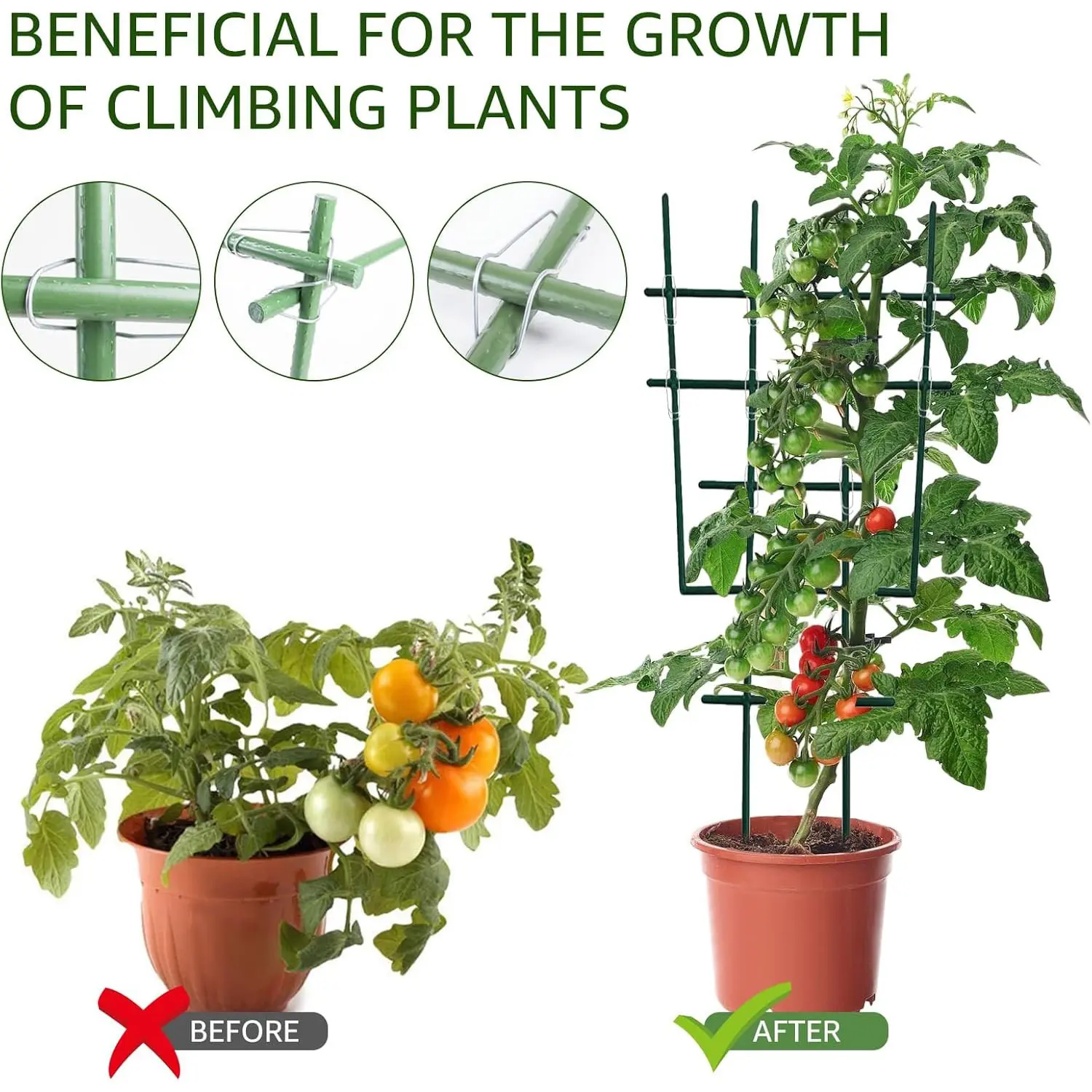

Their journey concludes with protection. Each buckle is nestled securely within tailored packaging – boxes or sleeves designed to guard against scuffs and impacts during shipping and storage, ensuring they arrive at your garden gate ready for years of steadfast service, holding bamboo and canes firm against the elements.