1. Material Sourcing & Initial Processing

Preparation of base materials commences the workflow.

2. Steel Tube Surface Treatment

Pipes undergo sequential conditioning:

Degreasing and rust elimination

Phosphating application

Moisture evaporation

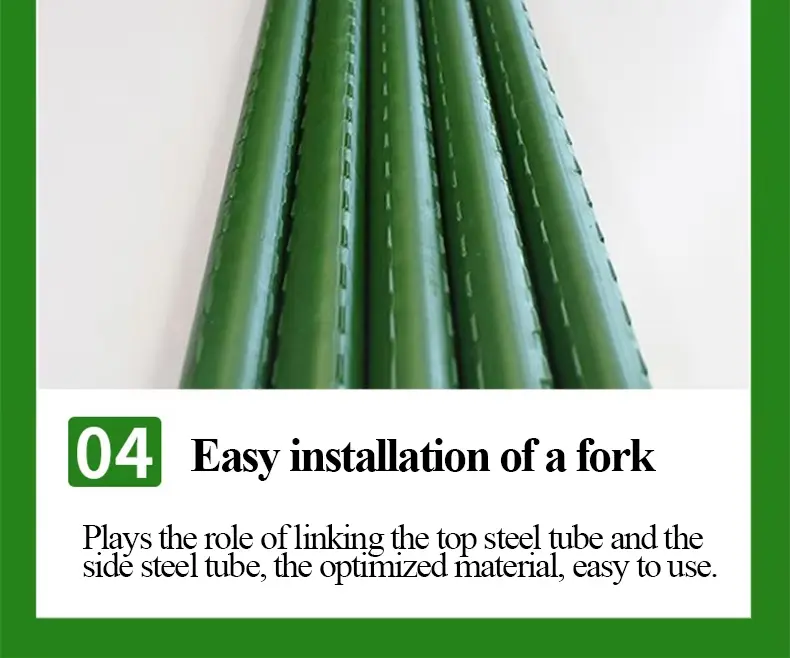

3. Electrostatic Coating & Fusion

Surface finishing involves:

Electrostatic deposition of polymer coating

Thermal curing at elevated temperatures

4. Thermal Regulation & Contouring

Treated pipes proceed through:

Controlled cooling (air/water mediums)

Dimensional stabilization

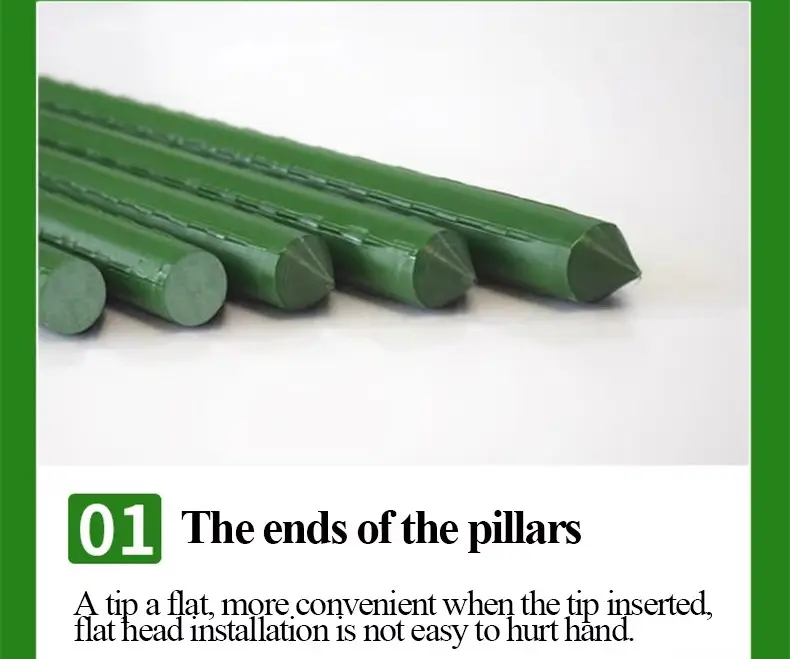

5. Precision Sizing & Shaping

Components are customized via:

Length-specific cutting

Angular tube forming

6. Hardware Integration

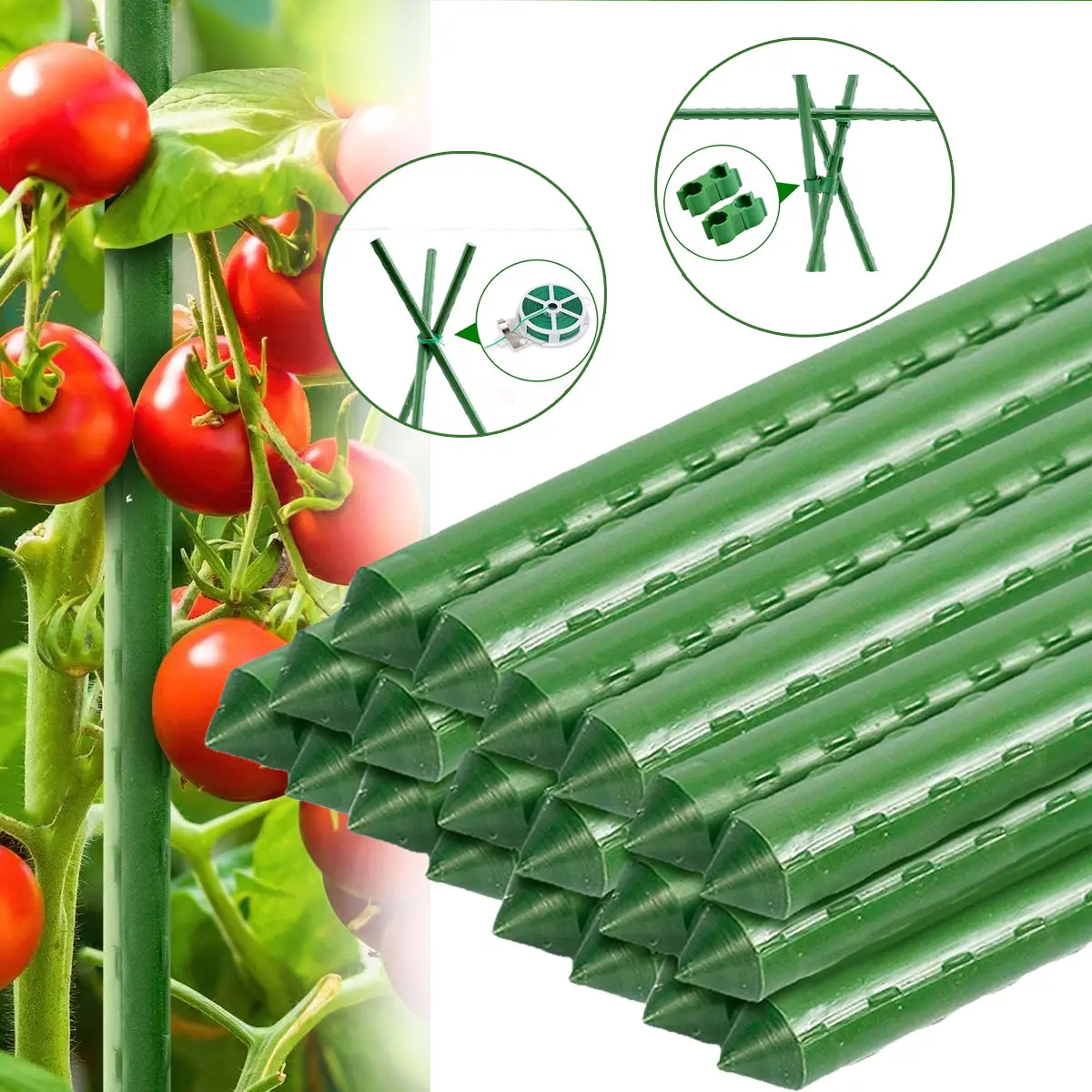

Pre-fitted components include:

Fastening buckles

Ground insertion plugs

Supplementary accessories

7. Protective Packaging & Inventory Management

Finalized products receive:

Dual-layer transit shielding (foam liner + woven sleeve)

Secure storage protocols

Prevents coating abrasion during logistics